Chapter I Model801, Model802 Functions and Features

1. Completely Compatible with the Seventh Generation Control System

The eighth generation is developed based on the seventh. Compared with the seventh, the eighth has all the functions of the seventh. Moreover, the eighth is more functional, more powerful, more stable and more reliable.

2. Supporting 210 colors

The seventh supports 28 colors: 28*28*28=16777216 kinds of colors.

The eighth supports 210 colors: 210*210*210=1073741824 kinds of colors. It needs to work with our video processors using the 30 bits TTL.

So the coloring number of the eighth is 64 times as much as that of the seventh.

3. The intelligent connecting function

Without resetting the configurations, the receiving cards (including spare ones) of the same LED display/cabinet can be randomly exchanged or replaced, for they will automatically recognize the showing area and content they are responsible for.

4. The intelligent supervision function

In each receiving card, there is a temperature sensor and four fan-power-output-ports. The speed of the fans is under wise controlled according to the warming value of temperature set by users.

5. Company Logo Showing

If the power of the sending card is not turned on, the monitor the PC will automatically show the preset company picture. The pixel of the picture will be 128*128, the coloring number 16K.

6. Supporting more scan mode

The seventh supports 1, 2, 4, 8, 16 scan mode, the eighth supports 1, 2, 3, 4, 5, 6, 7, 8, 9. 10, 11, 12, 13, 14, 15, 16 scan mode.

7. Supporting more modules

The seventh supports modules with the width: 2pixels, 4 pixels, 8 pixels, 16 pixels, 32 pixels, 64 pixels.

The eighth supports all the modules with width within 64 pixels. That is from 1 pixel to 64 pixels.

8. Supporting cut-up function

Each receiving card max supports 1024 pieces cutup, for non-conventional type display or text display use.

9. supporting empty pixel insert

The eighth can be set to insert one or more empty pixels every X pixels. This function is applying in non-conversional type display.

10. Supporting PWM driver chip

Need to use particular driver chip

Make the display effect going perfect

11. Supporting hardware pixel by pixel correction

Need to use particular driver chip. By changing the current for the LED, adjust the color, wave and brightness of the LED.

Make the effect of display pixel by pixel correction better.

12. Supporting pixel supervision function

Need to use particular driver chip

Dynamically check the bad pixels on the display.

13. Giga Technology

Veritable Giga technology. One sending card can support the max pixels: Model701: 1280*1024; model702: 2048*640; two cards are cascaded: 2048*1152. Single network cable supports the max pixels: model701: 1024*640, 1280*512; model702: 1600*400, 2048*320

14. Pixel by Pixel Correction and Unit box by Unit box Correction Function

Pixel by pixel correction supports four kinds of correction modes: single pixel, 2*2pixels, 4*4 pixels, 8*8 pixels; and the max correction is 6144 pixels/module, and brightness 256 levels for red, green, blue. Every unit box correction is used to adjust the chromatism among every unit box; and brightness 256 levels for red, green, blue.

15. Intelligent Identification Function

The intelligent identification program can recognize every kind of scanning mode and every type of signal trend of all kinds of double-color, full-color (real pixel and virtual pixel) drive boards, and the accuracy rate is 99%.

16. Gray level 0---Gray Level 66536 (64K) are Optional

Users can adjust the gray level from 0 to 66536 levels according to requirement of displays, making the display achieve the most desirable effects.

17. Optional Refresh Frequency, Synchronous function

Refresh frequency are adjustable from 10HZ to 3000HZ, and the refresh frequency and phase-lock function can make the display refresh locked at integral multiple of that of computer display, avoiding the image to been torn, and ensuring the image to be perfect. The phase-lock synchronous range is from 47HZ to 76HZ.

18. Super loading capacity

Full-color receiving card with gray level 4096 (Model 4K) and refresh frequency 180HZ can support 512*128; full-color receiving card (model 16K, only for static) with gray level 16384 and refresh frequency 300HZ can control 160*64,.(Remarks: the drive board must realize high frequency 30MHZ)

19. Double network cables switch automatically

The A and B ports of the receiving card can be both used as input ports or output ports. Users can adapt two computers to control a display at the same time, when one is out of order, the other will replace it automatically; Users can also use one computer with double network cables to control a display, when one is out of order, the other will take place of it automatically, making the display work normally all time.

20. Multi-display synchronous and combination functions.

Supporting one sending card to control multi-display, and the multi-display can be willful combination, synchronous display, and independent play.

21. Brightness 256 Levels Automatic Regulation

The function of brightness 256 levels automatic regulation can make the display brightness regulation more efficient.

22. Voice Transmission Function

Model 702 integrates the voice transmission, and requires no audio cable to transmit audio signals to the display. Double 24bits and 64KHZ hi-fi digital analogy and modulus switch to transmit the voice, making display achieve the perfect video effect.

23. Upgrading Program Online

If program of receiving card needs to be upgraded, just open the display power, and upgrade it through Led Studio, no need to remove the receiving card from the display.

24. No Toggle Switch

No toggle switches on the receiving card, all the setups are set through Led Studio.

25. Test Function

Receiving card has the test function, no sending card needed; can test the display directly, such as bias, gray level, red, green, blue, etc. many kinds of test modes.

26. Super Long Transmission Distance

The max transmission distance is 170M (actual measure); normal transmission distance is 140M.

27. Matching software

Led Studio V9.0 or above.

Remarks:

Sending card includes: full-color TS801, full-color TS802, double-color DS 801, double-color DS802

The differences between full-color system and double system:

double-color sending card can only be used for double-color display and single color display, but full-color sending card is suitable both for full-color (real pixel and virtual pixel) and double-color displays; however, double-color receiving card is the same as full-color one.

The differences between model 801 sending card and model 802 sending card:

Model801 can max support 1280*1024pixels

Model802 can max support 2048*1152pixels

Single card model 802 can control 2048*640pixels

Model802 has been added the voice transmission and cascade functions

Chapter II Model 801and 802 Manual

All the hardware setups are through the software—LedStudio.

I. Enter setup dialog box

Click the “software setup”, as shown in below figure;

And then will appear a dialog box, as shown in below figure;

As soon as the above dialogue box appears, input “linsn”, then password “168”. (Computer screen shows nothing when inputting “linsn” by keypad.), then enter setup dialog box, as shown in below figure

II. Sender setup

Display mode: if PC works under the 1024*768 resolution, nothing changes; otherwise choose the right resolution of PC, then click “Save on sender”. (Remarks:1024*768 resolution is recommended)

Default: when the LED display brightness dim suddenly without any reason, click Default and Save on sender will solve the dim problem.

III. Receiver setup

Before doing the configurations, get some knowledge of each item would do much help.

Drive chip: Optional for PWM chip, general chip and etc.

Present scan mode: after finishing intelligent setup, software will recognize the scan mode of the module.

File: after finishing intelligent setup properly, users will get a *.rcg file. Users can name it. For example: full-color 1/8 scan 8 rows/zone.

Led display refresh frequency: The higher the refresh frequency is, the more stable image will be on the screen. If a camera is used to shoot image on the LED display, to avoid ripple and flicker, user should set the refresh frequency above 600HZ. Generally speaking, for double-color screen, refresh frequency set as 60—75HZ; For indoor full-color display, 180—600HZ; For outdoor full-color display, 300-1200HZ.

Synchronous frequency: For bi-color display, it doesn’t matter; for tri-color display, this item has to be ticked.

Gray level: In general, gray level 256 is Ok for double-color display; 4096 for indoor display; 16384 for outdoor display. The higher the gray level is, the better the image will be.

Scan clock: the max scan clock is up to the design and performance of drive board. If drive board has a reasonable design and good performance, it can reach high scan clock, so single receiving card can support more pixels.

Duty ratio: it is the duty ratio of scan clock, changing this will affect the scan clock. Generally, the duty ratio is 50%.

Blanking time: It is used to fix brightness leak. Set 3000 for double-color display; 200 for full color display. (Real pixel and virtual pixel).

Gray equalize: The default value is 1; generally, most Led screens don’t need to adjust this item. The normal gray displays from darkness to brightness, as shown in below figure:

Some panels are not of good quality, so the gray level doesn’t display regularly; if users adjust this item, it is possible to make the gray level normal. The adjust value range: 0-15.

Virtual display: if the led display is virtual display, and it works under virtual mode, user should tick this item.

Max width: Pixels that one receiving card can max support. It is related with refresh frequency, gray level and scan clock, and it will change accordingly to the three items. Normally, raise up the refresh rate and the gray level will low down the max width; but reverse to the scan clock.

Actual width: actual width of one receiving card need to support.

Max height: Pixels one receiving card can support for the height. It is relevant to the design of led display drive board.

Actual height: actual height of one receiving card need to support.

Intelligent setup: There are 7 steps. (Some steps will be skipped according to different display panel.) By doing the intelligent setup, Linsn controllers will fetch the info of the led display, such as scan mode, chip decode, module size, signal trend etc, then apply the suitable connecting program from the firmware. Before doing the intelligent setup, user must collect the info of the following picture: the info can also get from the led display manufacturer.

Load from files: If user get a .RCG file from the manufacturer or user have generate a .RCG file by doing intelligent setup before, for the same kind led display, user can upload the .RCG file and make the display work fine.

Save on files: If user has made a successful intelligent setup, there should be a .RCG file generated. By saving on files, user can save the .RCG file.

Send to receiver: After finishing the intelligent setup, or change any parameters, or upload any .RCG or .CON files, user has to click “send to receiver” to take effect on the led display.

Save on receiver: Click this item can save data in receiving card permanently. If not, the data lost when power is down.

Intelligent setups are shown below: (Make sure the correct connection for the flat connected panel with hub card, otherwise the “Intelligent setup” can’t recognize your panel properly. Entering the setup interface, users must do the operation and watch testing panel carefully at the same time, because all the operation setups must follow the panel’s instructions. )

1. Click the “intelligent setup”

2. Choose the type of display (Single-color, double-color, full-color real pixel, full-color virtual pixel.)

If display is virtual pixel, you should choose the right virtual pixel sequence; there are four choices in total, as shown in below figure.

(Notice: one virtual pixel consists of two red lights, one green light and one blue light. The up row one is red A, and the down row one is red B.)

3. Input the pixels of a module (also called panel, shown in below figure), width (X), height (Y);

4. Input the quantity of the data input port, and the quantity of data group for every data input port, taking the full-color as an example, data input port-- how many data input ports at back of each full color module; Data group-- how many R, G, B data groups for a full color module. as shown in below figure

5. Data type, (red, green, blue) red, green and blue unite as one, three colors serial; red, green and blue unite as one, four colors serial. Generally speaking, the first data type (Red, green, (blue) separately) for Led display, the other items for light-decoration.

6. Choose the row decode mode (Unknown or not in the following options\static, no decode\no decode chip, row drive directly, with OE\no decode chip, row drive directly, no OE\chip 138 decode\chip 139 decode\chip 145 decode\chip154 decode\chip 164 decode\chip 192 decode\chip 193 decode\chip 595 decode\chip 4094 decode)

7. Module cascade direction: how signal goes. look from the front of LED display: data from right to left; from left to right; from top to down; from down to top. Choose the right one according to your cascading modules.

8. Watch module change: choose the right status, for example, status 1 shows white, and status 2 shows black.

9. Watch the module, and choose the right status.

10. Compared status 1 with status2 of the module, watch which one is brighter, for example: status 1 is brighter than status 2. Choose the right one.

11. Watch the color that the module shows, for example, status 1 displays red, and status 2 displays green. Select the right one.

12. Watch the module: one row is bright or multiple rows are bright; when multiple rows are bright, check how many interval rows. As shown in below figure.

Notice: Interval rows mean how many black (dim) rows between two bright rows, and then add one bright row for the total interval rows. (You must figure out all the bright rows in the panel, but for the interval rows, you only need to figure out how many rows between two bright rows.) For example, as shown in below figure, there is one black (mid) row between two bright rows, choose 2 (1+1=2) rows for the interval rows, 4 rows for bright row.

If there is no black (mid) row between the bright rows, select 1 row for the interval row, as shown in below figure: 4 rows for bright rows, and 1 for interval row.

Choose the right one according to your module.

13. Watch which pixel is bright in the module, then click the corresponding grid on the computer screen, after clicking the grid, you will find another pixel will be bright on the module, then you continue to click the corresponding grid on the computer screen, after click it, another pixel will be bright on the module…. By analogy, follow the instruction on the module; the computer will inform you when all the pixels are choice-finish.

14. After finishing “intelligent setup”, send it to the receiver; if saving it (.RCG) into file in computer, you can load it from the file directly when you use this kind of module next time.

15. Setup the refresh frequency and gray level according to requirement of your Led display.

Pixel by pixel/ module by module correction: It includes four modes: single pixel; 2*2 module; 4*4 module; 8* module.

The single pixel mode can support the max 6144 pixels. If surpass 6144 pixels, please choose other modes.

Pixel by pixel correction data setup steps

(1). Setup actual width pixel and actual height pixel for your display (cabinet), and then click “Send to receiver”.

(2).Choose the correction mode: Single pixel, 2*2 module, 4×4 module, 8×8 module. (Remarks: single pixel correction can support the max pixel 96*64=6144, if surpass, please choose other correction modes.)

(3). Click “Edit correction data”, shown in below figure.

① Correction by hand: Select the color that needs to be corrected (red, green, blue), and choose the pixels that require to be corrected, using ctrl key can select multiple pixels; then click “Add brightness” or ”lower brightness”, adjust the ideal brightness, as shown in below figure,

and then click “Submit”, then click “Send to receiver”; click” Save to receiver” can save it permanently. Making a backup in the computer file in order not lose the data.

② Create from picture:

A: Use high-class professional camera. Pixel resolution should be over 10 million pixels; advising to use CANON, EOS400D and CANON EOS5D, and EOS400D has been tested already, the effect is good. B: Set the receiving card no gray level or gray level 4 or gray level 8, and refresh frequency above 1500HZ, and tick the item “Synchronous refresh”.

C: Make screen display red, green, and blue separately; take 3 to 5 pictures for each color. (Request: fix the camera on a tripod rest; taking the pictures which can see every single pixel clearly)

D: Transmitting the pictures to computer, click “Create from picture”, as shown in below figure

And click “Add file” to add the pictures; then click the four corners of the LED display in the picture or parts of the led display that user wants to balance the brightness.

When select the picture, make sure every pixel is inside the four corners. After selecting, computer will mark all the pixels, as shown in below figure.

Check all the marked pixels, if error, click “Reset” for reselecting the four angles/corners for the picture;

If after several choices, and computer can’t mark all the pixels correctly, please click “Delete picture”, and then take three photos for the color again;

If you want to check brightness of every pixel, please click “View brightness”.

Select all the pictures of the led display/cabinet, the software will recognize how many pictures for each color (red, green, blue), and mark the value of lowest brightness pixel, highest brightness pixel and most pixels with same brightness. As shown in below figure.

E: Set the expected brightness value

F: After click “Save”, software will transfer the info of brightness of each picture into pixel correction data, and then fill into correction table. As shown in below figure.

(4). Click “Submit” first, and then click “Send to receiver”; after checking, click “Save on receiver”, and “Save on files”.

IV. Led display connection setup

1. First, Connect the display with control system correctly.

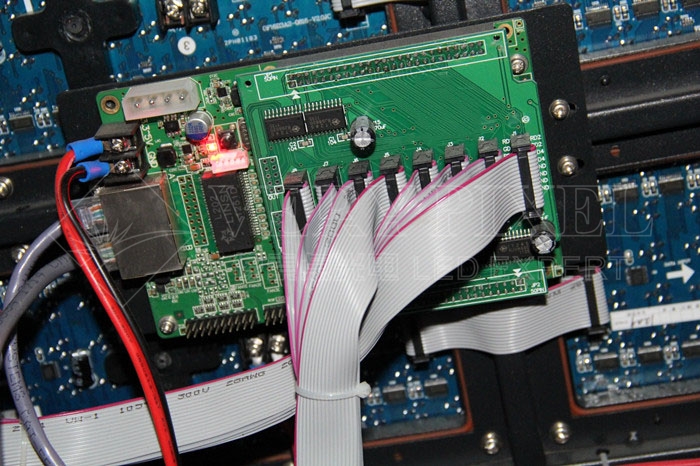

Lights on the sending card and the receiving card: Green lights for signal should be blinking; Red lights for power should be on.

Sending card: If the green light is not blinking: check the “clone” of the graphics card and open “clone”. Make sure the RS232 (serial cable) is connected. Reinstall the driver of the graphics card and click “Default” in “Option”-“software setup”- input “Linsn”-“168”-“sender” would solve the data problem in the sender.

2.Shown in below figure, click “Display connection”, input display QTY, for example, if a sending card supports 3 displays, input number: 3, if one, input number: 1;then click “Update display QTY ”,

Setup type of screen, such as full-color, double-color, etc.,

Input the card qty, X (width), Y (height), and then the computer will show the connection scheme, (Remark: the connection scheme is the copy as you face the Led display; one small box stands for a receiving card)

The receiving card that first gets signals from sending card is Order No.1,

Then input figures, for example, main cable: No.1, extension cable: 1, order No.: 1, width: 192, height: 128;

Remarks: mail cable: because maximum four sending cards can be cascaded, and each sending card has two signal-output ports, there are 8 options for choosing. “1 No. sender U cable (1U)” means the cable connect to the U port (near the lights) of the first sending card.

The receiving card connected with the fist receiving card as Order No. 2, then input figures;

Click “Send to receiver”. Each receiving card can be set to support the same pixels or different pixels or no pixel (suitable for irregular screen.),

Send the data to receiving card or save it (.CON) in the computer file.

The upper box means: one sending card supports two displays, one (Display 1) uses the U port of the sending card, the other (Display 2) using the D port of the sending card.

The upper box is the display connection of display1. Display 1 is real pixel; has four receiving cards,; when user looks at the front side of the display, the first receiving card is placed at the left top cabinet , supporting 120 pixels width, 48 pixels height.

The following box is the display connection of display 2. Display 2 is virtual pixel and showing signs in virtual mode. Display 2 has two receiving card. One receiving card supports 48 pixels width, 48 pixels height; the other receiving card supports 128 pixel width and 128 height.

Chapter III the Communication Cable Making Method

The making method is the same as that of international standard network cable(RJ45). It has two types: 568A and 568B, and we usually use 568B.