VERYPIXEL ONLY OFFERS QUALITY PIXELS

Our core value is to create the maximum value for our customers. So we design novel and creative products for the market.

● Verypixel is a professional LED display solution offer, designer & manufacturer founded by 6 key engineers of LED display industry

● What we supply is not only highly reliable Products, but more professional Solutions & extended Services

● We have 4 engineers who have been working in LED display industry for over 12 years

● We are good at customized, complicated and integrated systems

● Our 15 experienced engineers are waiting for supporting you

● We have already done over 1000 projects all around the world

You might already be familiar with the great things an LED display can do for your business or organization — bring in sales increases of 15% to 150%, grow public visibility, streamline your advertising budget — and now you're ready to source the right suppliers.

Our Specialty is As Below

Best solution & service for your projects

Best solution & service for your projects

- Based on our rich LED sign industry experience, professional knowledge and broad product line, Verypixel can supply best solution and service for your projects.

Highly reliable products

Highly reliable products

- Based on high responsibility to our customers, we insist on adopting high-quality LED and other components, and carrying on strict quality controlling system, so our products are much more reliable.

Easy maintenance with Verypixel breaking-through designings

Easy maintenance with Verypixel breaking-through designings

- Verypixel have strong R&D team with 15 professional engineers and 4 of them with over 10 years’ industry experience. Verypixel is famous on customization and continuous technical support for long-term in the whole industry.

VERYPIXEL QUALITY CONTROL

Verypixel quality controlling system mainly composed of four steps:

1. Raw material quality controlling system

2. Production quality controlling system

3. Aging, assembly production and finished product waterproof testing

4. Packaging and loading

|

|

Temp and humidity controlled warehouse.

Dust-free and antistatic protection for all raw materials

|

|

|

Voltage, current and brightness uniformity testing

performance secures quality of LED lamps.

|

|

|

LED lamps appearance, such as shape, encapsulation

and material color and down-voltage quality inspection

and control.

|

|

|

LED lamps wavelength, color temperature, brightness,

and wave edges study ensures the LED lamps’ uniformity.

|

|

|

Cabinet metal part and PCB quality control with salty,

humidity test equipment.

|

|

|

Silicon glue testing ensures the silicon glue from raw

material supplier will not crack and decay, which ensures

VP products’ waterproof system.

|

|

|

Module, cables, power supply and controlling system

temp and humidity programmable testing.

|

|

|

Brightness, color temperature and wavelength of LED

sample module and LED display panel.

|

|

|

SMT, Tin printing and Soldering positioning testing.

|

|

|

SMT and electronics components position quality inspection.

|

|

|

Wave soldering for LED lamps to PCB board, and

other connection components positioning and soldering

joints.

|

|

|

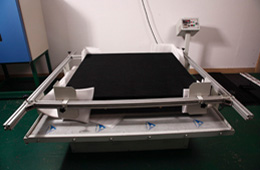

The machine can control the quantity of glue and

maintain the modules dried in a perfect horizontal

environment.

|

|

|

Module aging testing ensures the working performance

and uniformity. Test modules’ voltage, current, resistance

and capacity.

|

|

|

Waterproof testing ensures outdoor products meet IP65

requirement. This machine will dip the cabinet inside water

for 3 minutes.

|

|

|

Display aging test ensures the controlling system,

ventilation system , power system and supporting system

working together for at least 72 hours. No issues will be

left for customers.

|

|

|

Transportation imitation to test the durability of parts

assembly production line and ensures the products won’t

loosen during the water or air cargo transportation.

|

|

|

Reinforced wooden package and using foam cushion inside

the package to well protect the products.

|

|

|

We use forklifts to load the products, which could ensure

stable and safe moving for the products.

|