Tag: LED Display Manufacturer, LED PCB Board, LED Unit Board, LED Modules, LED Display Quality Control

How to distinguish the LED unit board is good or bad? Following Verypixel will tell you some ways on how to distinguish the LED unit board.

How to distinguish the LED unit board is good or bad? Look at the material!

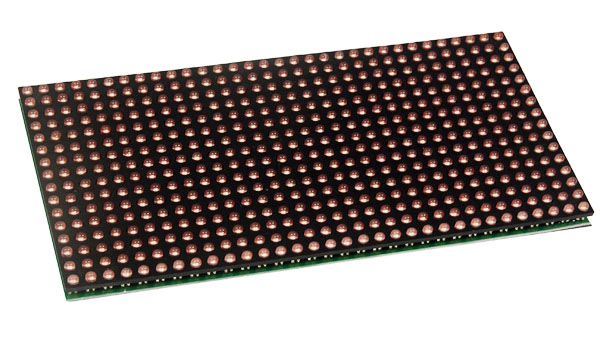

1. LED unit board material: Some of the LED unit board manufacturers adapt the cheap flame retardant paper board or single fiber board as PCB line of LED lamp board for lower price competition. Because the all glass PCB is too expensive. At the beginning ,there is no different in the display effective, if it is lucky, it can be used in half a year or eight months, in the normal case, it will be broken due to damp, UV damage, oxidation and other reasons, then all the LED unit board will be useless. High quality LED unit board must be use PCB with double glass plate, though the price is a little high ,quality is superior.

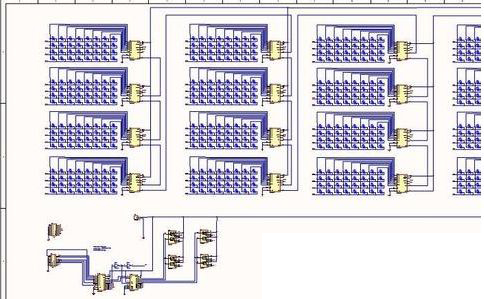

2. IC: You should observe the brand of IC device whether there is the same consistency. What is the type of IC, and how many IC you use can affect the board quality. In order to save costs, some businessman educe the number of IC intentionally when they produce unit board , or use some other brands of IC. IC is different, how can you ensure the stability of the board performance?

3. Beads and chip: it can't be distinguished whether the beads is good or bad just by your eye. Only by testing for a long time which experts say aging test. General small workshop always do like this: it will be electricity before leaving the factory, and check the LED display screen whether it can normal operate, it won't last long time to go through aging test. Because they cannot afford time costs and labor costs.

How to distinguish the LED unit board whether it is good or bad? Specific methods of examination!

1. Check the appearance of material's quality

① The PCB board and the processing quality;

② The IC device brand and consistency;

③ LED dot matrix character.

2. Check the circuit design and circuit design specification, PCB wiring need to meet LED display technology requirements.

3. Check the welding quality

Check the patch whether there is a leakage, wrong patch and the component pins burr short-circuit phenomenon. Check whether the plug weld straight is smooth, surface is clean and tidy, no weld weld or not . Check the LED dot matrix inserted is smooth and the ink color is consistence.

4. Power test (refer to "performance test report" steps)

① The electricity conformance test luminous dot matrix;

② Power test for driving tube CEM4953 is an effective protection;

③ Power test signal transmission capacity.

VERYPIXEL is a LED display production and sales company which collect the scientific research, production, sales, engineering and technology. The company is in good faith-based, meeting customer demand as the last, producing quality product as the center, promoting team spirit of "truth-seeking, unity, innovation" , it has the professional technology background, advanced technical team. Try our best to provide high quality, reasonable price, customer satisfaction products for customers.